How to Choose the Best Handheld RFID Reader for Your Business

In the relentless pursuit of efficiency and accuracy, businesses are constantly turning to technology to streamline their operations. For inventory management, asset tracking, and logistics, few technologies are as transformative as Radio-Frequency Identification (RFID). It promises the ability to identify dozens of items in seconds without a direct line of sight, a monumental leap over manual scans or even traditional barcodes.

But the power of RFID is only as good as the tool you use to harness it. Selecting the right handheld RFID reader is not a one-size-fits-all decision; it's a strategic investment that can redefine your operational workflow. This guide will walk you through the critical factors to consider to ensure you choose the perfect companion for your business needs.

1. Understand Your Primary Use Case: The "Why" Before the "What"

Before diving into technical specifications, start with a clear business objective. The environment and application will dictate the required features.

-

Inventory Management: Do you need to perform rapid warehouse cycle counts? A reader with excellent bulk reading capabilities and a long-range is key.

-

Asset Tracking: Are you tracking high-value tools, IT equipment, or medical devices in a large facility? Durability and locationing features might be paramount.

-

Retail & Apparel: In a busy store, you need a sleek, user-friendly device that integrates with your Point of Sale (POS) system and can quickly verify stock on shelves and in backrooms.

-

Field Service & Logistics: For outdoor use, tracking items in a yard, or loading trucks, you’ll need a rugged device with a long-range and advanced GPS capabilities.

-

Authentication & Security: Checking credentials or authenticating high-value goods? You might prioritize a specific frequency or security protocol.

2. Frequency Matters: UHF, HF, and NFC Explained

This is the most crucial technical differentiator. RFID readers operate on different frequencies, and choosing the wrong one will render your system useless.

-

UHF (Ultra-High Frequency, 860-960 MHz): This is the workhorse for modern supply chain, logistics, and inventory applications. It offers a long read range (up to 15+ meters in ideal conditions) and can rapidly read a large number of tags simultaneously. This is ideal for pallet tracking, warehouse inventory, and retail apparel.

-

HF (High Frequency, 13.56 MHz): Offers a shorter read range (up to ~1 meter) and is less effective for bulk reading. However, it is the global standard for applications like access control, patient tracking, library book management, and smart cards due to its better performance near metals and liquids.

-

NFC (Near Field Communication): A subset of HF that requires very close proximity (a few centimeters). It’s ubiquitous in smartphones for contactless payments and data sharing. Handheld readers with NFC are perfect for retail checkout, interactive marketing, and authentication tasks.

For most industrial and inventory applications, UHF is the default choice.

3. Form Factor: Handheld, Pistol-Grip, or Phone-Centric?

How your team will use the device daily is a significant ergonomic consideration.

-

Traditional Handheld / PDA Style: These all-in-one mobile computers resemble a thick smartphone. They integrate the RFID reader, a display, a keypad (or touchscreen), and a operating system (like Android) into a single, rugged unit. They are powerful and self-contained but can be a larger investment.

-

Pistol-Grip Triggers: Designed for high-volume scanning in warehouses. The form factor is easy to hold for long periods, and the trigger allows for intuitive control over scanning. They are often extremely rugged.

-

Sleds/Bluetooth Add-ons: These are modules that attach to a standard smartphone or tablet (e.g., via Bluetooth) to give it RFID capabilities. This is a cost-effective way to leverage consumer hardware for occasional use but often lacks the durability, battery life, and integration of a dedicated device.

4. Ruggedness and Environmental Rating

If your device will be used in a warehouse, factory, or outdoors, it cannot be fragile. Look for industry-standard ratings:

-

IP Rating (Ingress Protection): e.g., IP65 means it is dust-tight and protected against low-pressure water jets. IP67 allows for temporary immersion in water.

-

MIL-STD-810H: This U.S. military standard certifies the device can withstand drops onto concrete (e.g., from 1.5m or 1.8m), extreme temperatures, vibration, and humidity. A high drop spec is critical for longevity in demanding environments.

5. Battery Life: Don't Get Caught with a Dead Reader

There's nothing worse than your scanners dying mid-inventory count. Battery performance is critical.

-

Shift-Life Battery: The gold standard is a battery that can last a full 8-12 hour shift (or even multiple shifts) on a single charge, even with heavy RFID and Wi-Fi use.

-

Hot-Swappable Batteries: For 24/7 operations, a device that allows you to swap the battery without powering down is a massive advantage. This ensures continuous operation.

-

Battery Chemistry: High-quality Lithium-ion batteries are standard, but check the rated capacity (often in mAh).

6. Connectivity and Integration

The reader is a data-capture tool; it must seamlessly deliver that data to your central system.

-

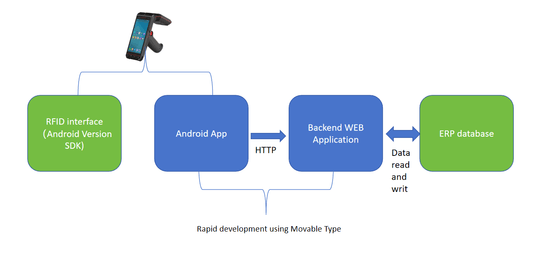

Wi-Fi & Bluetooth: Essential for real-time data sync to your warehouse management system (WMS) or ERP software. Dual-band Wi-Fi (2.4GHz and 5GHz) ensures a stable connection.

-

Cellular (4G/LTE, 5G): Critical for field service technicians or yard management where Wi-Fi is unavailable. It enables real-time updates from anywhere.

-

GPS: For logistics and yard management, geofencing and pinpointing the exact location of an asset are invaluable.

-

Software & APIs: Ensure the device is supported by a robust Software Development Kit (SDK) so your IT team or solution provider can seamlessly integrate it into your existing software ecosystem.

7. The Total Cost of Ownership (TCO)

Look beyond the initial sticker price. Consider:

-

Durability: A cheaper, non-rugged device may break quickly, leading to high replacement costs and operational downtime.

-

Software & Support: Are there ongoing licensing fees? Is the vendor's technical support responsive and knowledgeable?

-

Ease of Use: A device that is intuitive and requires minimal training will save you money in the long run on onboarding and reducing errors.

Introducing the LS-R501: A Prime Example of Modern RFID Power

After considering all these factors, you'll recognize a well-designed reader when you see one. A prime example that encapsulates these best-in-class features is the RFID Handheld Mobile Computer LS-R501.

The LS-R501 is engineered for performance in the most demanding environments. It’s a powerful UHF RFID handheld that doesn’t just meet the checklist—it excels at it. Built to the rugged IP65 rating and capable of surviving repeated drops to concrete, it’s ready for the rigors of a warehouse or distribution center.

Its ergonomic pistol-grip design ensures operator comfort during long shifts, while its powerful battery is designed for all-day, high-intensity scanning operations. Running on a versatile Android platform, it offers the flexibility to run a wide array of applications and ensures easy integration into your existing software infrastructure. With advanced data capture capabilities, including long-range UHF RFID, barcode scanning, and optional NFC, the LS-R501 is a true all-in-one data capture powerhouse.

Choosing the best handheld RFID reader is a detailed process, but by focusing on your use case, the technical requirements, and the real-world demands of your workforce, you can select a tool that will drive efficiency, accuracy, and ROI for years to come. A device like the LS-R501 represents the culmination of these considerations, offering a robust and reliable solution designed to empower your business in the digital age.

No comments

0 comments