The Ultimate Guide to Choosing an Industrial Printing Handheld Terminal

In today's fast-paced industrial environments, efficiency and accuracy are paramount. From warehouse logistics and manufacturing to retail inventory and field service, the ability to capture data, process information, and produce physical records on the spot is a game-changer. This is where the Industrial Printing Handheld Terminal comes into play. More than just a scanner or a mobile computer, this all-in-one device is a powerful tool that streamlines operations, reduces errors, and enhances productivity.

But what exactly is an industrial printing handheld terminal, and why is it becoming an indispensable asset across various sectors? More importantly, how do you choose the right one for your business? This comprehensive guide will walk you through everything you need to know.

What is an Industrial Printing Handheld Terminal?

An industrial printing handheld terminal is a robust, portable device that combines the functions of a mobile computer, a data capture tool (like a barcode scanner or RFID reader), and an integrated printer. Unlike traditional setups where a worker might carry a separate scanner, mobile device, and a portable printer, this technology consolidates all these features into a single, ergonomic unit.

Running typically on operating systems like Android, these terminals are designed for use in demanding environments. They are built to withstand drops, dust, water, and extreme temperatures—conditions that would easily damage consumer-grade devices.

Key Benefits of Using an Industrial Printing Handheld Terminal

-

Unmatched Efficiency and Time Savings

The most significant advantage is the consolidation of multiple tools into one. Workers no longer need to waste time moving between a fixed workstation and a task location or juggling multiple devices. They can scan an item, verify its information on the spot, and immediately print a label, receipt, or ticket right from their hand. This seamless workflow drastically reduces process time and minimizes movement. -

Elimination of Errors

In traditional processes, data is often captured on one device and then manually transcribed or transferred to another system for printing. This manual handoff is a common source of errors. With an all-in-one terminal, data is captured digitally and the print output is generated automatically, ensuring 100% accuracy between the scanned data and the printed label. -

Enhanced Mobility and Flexibility

These devices liberate workers from the warehouse desk or the retail counter. Tasks like cycle counting, price marking, asset tagging, and proof-of-delivery can be completed anywhere on the facility floor or out in the field. This mobility allows businesses to reimagine their workflows and deploy staff more dynamically. -

Improved Customer Service

In field service or direct-to-consumer applications, technicians and drivers can provide immediate, professional invoices, receipts, and work summaries upon job completion. This professionalism enhances the customer experience and accelerates the payment process. -

Durability and Lower Total Cost of Ownership (TCO)

While the initial investment may be higher than buying consumer devices, industrial terminals are built to last. Their rugged design means they survive accidents that would destroy regular smartphones or tablets, leading to far fewer replacements and repairs. Over time, this durability, combined with massive gains in worker productivity, results in a significantly lower TCO and a strong return on investment (ROI).

Critical Factors to Consider When Choosing a Terminal

Selecting the right terminal is crucial. Here’s what to evaluate:

-

Printing Technology and Quality

Most integrated printers use thermal technology, either Direct Thermal (for temporary labels like shipping labels) or Thermal Transfer (for durable, long-lasting labels for asset tagging). Consider the print width (2-inch, 3-inch, 4-inch), print speed (inches per second), and resolution (clarity of the print) to ensure it meets your labeling needs.

Introducing the LS-P501: The Powerhouse for Demanding Applications

After considering all these factors, it becomes clear that a terminal must excel in every category to deliver true value. A prime example of such a device is the Industry Printing Handheld Terminal LS-P501.

The LS-P501 is engineered to meet the toughest industrial challenges. It seamlessly integrates a high-speed thermal printer, a superior 1D/2D barcode scanner, and optional UHF RFID into a single, ruggedized Android computer. Built to IP65 standards and capable of surviving multiple 1.5-meter drops to concrete, it is designed to thrive in the harsh conditions of a warehouse, factory, or logistics yard.

What sets the LS-P501 apart is its focus on user-centric productivity. Its ergonomic design ensures comfort during extended use, while its large battery capacity supports a full day of intensive printing and data capture. The bright, responsive touchscreen provides clear visibility indoors and out, and its powerful connectivity options ensure seamless integration into your enterprise ecosystem.

Whether you’re printing shipping labels, asset tags, compliance certificates, or delivery receipts, the LS-P501 delivers unparalleled accuracy and efficiency right in the palm of your hand.

Conclusion

Investing in an industrial printing handheld terminal is a strategic decision that drives operational excellence. By consolidating critical functions into a single, durable device, businesses can eliminate bottlenecks, empower their mobile workforce, and achieve new levels of accuracy and efficiency.

When evaluating options, prioritize ruggedness, printing capabilities, and seamless integration. For a solution that embodies all these qualities and is ready to transform your operations, the LS-P501 stands as a reliable and powerful choice, built to perform where it matters most.

-

Data Capture Capabilities

Identify what you need to scan:-

Barcode Scanning: Look for a high-performance imager that can read 1D/2D barcodes from screens or damaged labels.

-

-

Ruggedness and Build Quality

Check industry-standard ratings:-

IP Rating: Look for at least IP54 for dust and splash resistance, with IP65 or IP67 being ideal for harsher environments.

-

Drop Specification: The device should withstand repeated drops to concrete from at least 1.5 meters (5 feet).

-

-

Battery Life

Printing is power-intensive. The device must have a high-capacity battery capable of lasting a full shift (8-12 hours) with heavy printing and scanning use. Hot-swappable batteries are a huge advantage for 24/7 operations. -

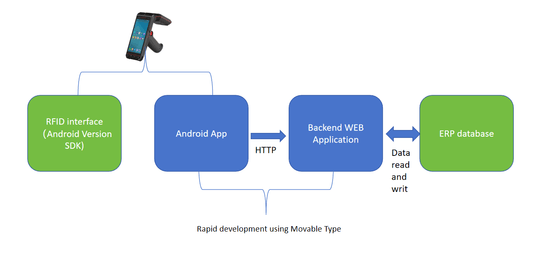

Connectivity and Integration

Ensure the device has robust Wi-Fi, Bluetooth, and optional 4G/LTE to keep workers connected to your central management system (ERP, WMS) in real-time. It must also be compatible with your existing software, often facilitated by an Android SDK for easy application development. -

Ergonomics and Usability

A device that is too heavy or awkward to hold will slow down workers and cause fatigue. The right balance of screen size, keyboard/touchscreen interface, and overall weight is essential for all-day comfort.

No comments

0 comments