Challenges in Hybrid (RFID + Barcode) Warehouse Environments

Amid complex supply chains, warehouses increasingly adopt hybrid RFID + barcode systems. Yet integrating these technologies brings unique challenges. This blog explores these hurdles and how Leeshion’s Long-Range Handheld UHF RFID Reader unlocks the hybrid system’s potential.

Understanding the Rationale for Hybrid (RFID + Barcode) Systems

Before diving into the challenges, it’s critical to understand why warehouses are embracing hybrid RFID and barcode systems. Barcodes have been a staple in warehousing for decades, offering low-cost, reliable identification for individual items. They are ideal for scenarios where precision at the item level is paramount, such as e-commerce order fulfillment, and work well with existing point-of-sale (POS) and warehouse management system (WMS) integrations. On the other hand, UHF RFID technology excels in high-volume, fast-paced environments. Unlike barcodes, which require line-of-sight scanning, RFID tags can be read from a distance, through packaging, and in bulk—enabling warehouse staff to scan dozens of items in seconds rather than minutes.

The hybrid model combines these strengths: using RFID for large-scale operations like receiving, putaway, and inventory counts, and barcodes for item-level verification during picking, packing, and shipping. For example, a warehouse might use RFID to quickly scan an entire pallet of goods upon arrival, then rely on barcodes to ensure the correct individual items are picked for a customer order. This combination optimizes both speed and accuracy, but it also introduces layers of complexity that single-technology systems don’t face.

Key Challenges in Hybrid Warehouse Environments

1. Interoperability Between RFID and Barcode Systems

One of the most significant challenges in hybrid environments is ensuring seamless interoperability between RFID and barcode technologies. These two systems operate on different principles, use different data formats, and often rely on separate hardware and software solutions. For instance, barcode scanners typically read linear or 2D codes and transmit data in a straightforward, human-readable format, while UHF RFID readers communicate with tags via radio waves, transmitting encrypted or standardized data (such as EPCglobal) that may require translation for WMS compatibility.

The problem is compounded when warehouses use legacy barcode systems alongside new RFID deployments. Many older WMS platforms are not natively designed to handle RFID data, leading to data silos where information from RFID scans and barcode scans exists in separate systems. This disconnect can result in inaccurate inventory records, delayed order processing, and increased manual data entry—undermining the very efficiency gains the hybrid system was meant to deliver. For example, if an RFID scan of a pallet is not synced with the WMS that tracks barcode-based item picks, the system may show conflicting inventory levels, leading to stockouts or overstocking.

2. Data Management and Synchronization

Closely tied to interoperability is the challenge of data management and synchronization. Hybrid systems generate massive volumes of data from both RFID and barcode scans, and warehouse operators must ensure this data is consistent, accurate, and real-time. RFID, in particular, can produce a flood of data when scanning multiple tags at once—for example, during a full inventory count of a rack with hundreds of items. If this data is not processed and synchronized with barcode data in real time, it can lead to discrepancies that are difficult to resolve.

Another data-related challenge is tag and code standardization. Warehouses may use a mix of RFID tags (passive, active, different frequencies) and barcode types (UPC, QR codes, Code 128), each with its own data structure. Ensuring that all these tags and codes contain consistent, standardized information (such as product IDs, batch numbers, and expiration dates) is a logistical nightmare. Without standardization, data from different scans cannot be easily correlated, making it impossible to get a unified view of inventory or order status.

3. Hardware Compatibility and Integration

Deploying a hybrid system requires investing in hardware that can handle both RFID and barcode scanning—and ensuring that this hardware works seamlessly together. Many warehouses start with barcode scanners and later add RFID readers, leading to a hodgepodge of devices from different manufacturers. These devices may use different communication protocols (such as Bluetooth, Wi-Fi, or USB) and may not be compatible with the same mobile devices or WMS software.

For example, a warehouse might have a fleet of barcode scanners that connect to Windows-based mobile computers, while the new RFID readers are designed for Android devices. This incompatibility forces staff to carry multiple devices—one for barcode scanning and one for RFID—slowing down workflows and increasing the risk of human error. Additionally, RFID readers require specific antennas and power sources to achieve optimal read ranges, which may not be compatible with existing warehouse infrastructure (such as shelving, lighting, or metal surfaces that can interfere with radio waves).

4. Environmental Interference

Both RFID and barcode technologies are susceptible to environmental interference, but the sources of interference differ—creating unique challenges in hybrid environments. Barcode scanning relies on line of sight, so factors like low lighting, dirty or damaged labels, and reflective surfaces can prevent accurate scanning. RFID, on the other hand, uses radio waves, which can be disrupted by metal objects, liquid products, and dense packaging. In a hybrid warehouse, operators must contend with both sets of interference issues simultaneously.

For example, a warehouse storing metal parts might use RFID for pallet-level tracking, but the metal shelves and products can weaken RFID signals, reducing read range and accuracy. At the same time, barcode labels on individual parts may become smudged or damaged by oil and dust, making them unreadable. Overcoming these environmental challenges requires careful planning—such as using specialized RFID tags for metal or liquid products, investing in high-performance scanners with advanced imaging technology for barcodes, and optimizing warehouse layout to minimize interference.

5. Staff Training and Adoption

Even the most advanced hybrid system will fail if warehouse staff are not properly trained to use it. Many warehouse workers are familiar with barcode scanners, which are simple to operate—point and scan. RFID readers, however, are more complex: staff must understand how to position the reader for optimal read range, how to interpret bulk scan data, and how to troubleshoot issues like missed tags or signal interference.

The learning curve is steeper in hybrid environments, where staff must switch between two different technologies and understand when to use each one. For example, a picker might need to use an RFID reader to locate a pallet, then switch to a barcode scanner to verify the correct item. Confusion about which device to use, or how to use them together, can lead to errors, delays, and frustration. Additionally, some staff may be resistant to adopting new technology, preferring the familiarity of barcodes. Overcoming this resistance requires comprehensive training programs, hands-on practice, and clear communication about the benefits of the hybrid system.

6. Cost Considerations and ROI

Implementing a hybrid RFID + barcode system is a significant investment. Costs include purchasing RFID readers, tags, and barcode scanners; upgrading WMS software to support interoperability; training staff; and maintaining the system. For small to mid-sized warehouses, these costs can be prohibitive, especially if the ROI is not clearly defined.

The challenge is that the benefits of hybrid systems—such as faster inventory counts, reduced labor costs, and improved accuracy—are often incremental and may take time to materialize. Additionally, many warehouses struggle to measure the ROI of hybrid systems because it’s difficult to separate the benefits of RFID from those of barcodes. For example, if inventory accuracy improves by 20%, how much of that improvement is due to RFID’s bulk scanning capabilities, and how much is due to barcode’s item-level precision? Without clear metrics, it’s hard to justify the investment to stakeholders.

Overcoming Hybrid Environment Challenges with Leeshion’s Long-Range Handheld UHF RFID Reader

While the challenges of hybrid warehouse environments are significant, they are not insurmountable—especially with the right technology partners and solutions. The Leeshion Long-Range Handheld UHF RFID Reader (20m Range, Android 13, IP65, SDK Included) is specifically designed to address many of the key pain points of hybrid systems, offering a versatile, integrated solution that bridges the gap between RFID and barcode technologies.

Let’s explore how this device addresses each of the challenges we’ve discussed:

1. Seamless Interoperability and WMS Integration

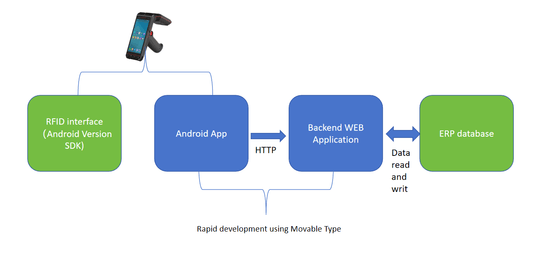

The Leeshion reader is equipped with both UHF RFID and high-performance barcode scanning capabilities (supporting 1D/2D barcodes), eliminating the need for separate devices. It runs on Android 13, a widely compatible operating system that integrates seamlessly with most modern WMS platforms. Additionally, Leeshion provides a comprehensive SDK (Software Development Kit) that enables easy customization and integration with legacy systems. This means that data from both RFID and barcode scans is transmitted in a standardized format to the WMS, eliminating data silos and ensuring real-time synchronization.

2. Efficient Data Management

With a 20-meter long read range, the Leeshion reader can quickly scan dozens of RFID tags in bulk—ideal for receiving, putaway, and inventory counts. At the same time, its advanced barcode scanner can read even damaged or low-contrast labels, ensuring accurate item-level data capture. The device processes and transmits data in real time, reducing the risk of discrepancies between RFID and barcode data. Additionally, the Android 13 operating system supports powerful data management apps, allowing staff to filter, sort, and analyze scan data on the go.

3. All-in-One Hardware Solution

By combining UHF RFID and barcode scanning in a single handheld device, the Leeshion reader eliminates the need for staff to carry multiple devices. This streamlines workflows, reduces human error, and lowers hardware costs. The device is also designed for durability, with an IP65 rating that makes it resistant to dust, water, and drops—critical for harsh warehouse environments. Its long battery life ensures that it can handle a full shift of scanning without recharging, further improving operational efficiency.

4. Enhanced Performance in Challenging Environments

The Leeshion reader’s long 20-meter read range and advanced antenna design minimize the impact of environmental interference. It can read RFID tags even through packaging or near metal surfaces, making it ideal for warehouses storing a variety of products. The barcode scanner uses advanced imaging technology that works in low light, dusty, or wet conditions, ensuring reliable scanning even when labels are damaged. This versatility makes the device well-suited for hybrid environments where both RFID and barcode technologies face interference challenges.

5. User-Friendly Design for Easy Adoption

The Leeshion reader features an intuitive Android 13 interface that is easy to learn, even for staff familiar only with barcode scanners. Its lightweight, ergonomic design reduces fatigue during long shifts, and the one-handed operation allows staff to switch between RFID and barcode scanning with minimal effort. Leeshion’s SDK also enables the development of custom apps tailored to specific warehouse workflows, making training even more effective. By simplifying the user experience, the device reduces resistance to adoption and accelerates the learning curve for staff.

6. Cost-Effective ROI

While the Leeshion reader represents an investment, its all-in-one design reduces hardware costs compared to purchasing separate RFID and barcode devices. Its efficiency gains—such as faster inventory counts (reducing labor time by up to 70% compared to manual or barcode-only scanning) and improved accuracy (reducing stockouts and overstocking)—deliver measurable ROI in a short period. Additionally, the device’s durability and long lifespan reduce maintenance and replacement costs, further enhancing its cost-effectiveness.

Best Practices for Successful Hybrid Warehouse Implementations

In addition to using the right hardware, there are several best practices that can help warehouses overcome the challenges of hybrid environments:

-

Start with a Clear Strategy: Define your goals for the hybrid system (e.g., improving inventory accuracy, reducing labor costs) and identify which processes will use RFID, which will use barcodes, and how they will integrate.

-

Standardize Data Formats: Ensure that all RFID tags and barcodes use the same data structure (e.g., EPCglobal for RFID, GS1 for barcodes) to enable seamless data correlation.

-

Test in Real-World Conditions: Before full deployment, test the hybrid system in your warehouse’s specific environment to identify and address interference issues, hardware compatibility problems, and workflow inefficiencies.

-

Invest in Comprehensive Training: Provide hands-on training for staff on how to use both RFID and barcode technologies, and how they work together. Offer ongoing support to address questions and concerns.

-

Monitor and Optimize: Track key metrics (e.g., inventory accuracy, scan time, labor costs) to measure the success of the hybrid system. Use this data to identify areas for improvement and optimize workflows over time.

Conclusion

Hybrid (RFID + barcode) warehouse environments offer a powerful combination of speed, accuracy, and cost-effectiveness, but they also present unique challenges—from interoperability and data management to environmental interference and staff adoption. Overcoming these challenges requires a strategic approach, including the right hardware, software integration, and training. The Leeshion Long-Range Handheld UHF RFID Reader is a key solution in this regard, offering an all-in-one, user-friendly device that seamlessly integrates RFID and barcode scanning, minimizes environmental interference, and simplifies WMS integration.

As supply chains continue to evolve, hybrid identification systems will become increasingly essential for warehouses looking to stay competitive. By addressing the challenges head-on and leveraging solutions like the Leeshion reader, businesses can unlock the full potential of hybrid systems, improving operational efficiency, reducing costs, and delivering better customer experiences. The future of warehousing is hybrid—and with the right tools and strategies, it’s a future that is both efficient and sustainable.

Comments

No comments

Leave a comment

Your Email Address Will Not Be Published. Required Fields Are Marked *

Popular Posts

Case Studies

Subscribe Us

Subscribe to our newsletter and receive a selection of cool articles every weeks

0 comments