Reshaping Inventory Efficiency: A Practical Guide to Integrating Handheld RFID with ERP and Inventory Systems

In today's fast-paced business environment, inventory management is no longer simply about "how much inventory is in the warehouse"—it's directly linked to the accuracy of procurement plans, the smoothness of production processes, the timely delivery of customer orders, and even the efficiency of a company's capital turnover. However, many companies are still stuck in the quagmire of traditional inventory management: manual counting is time-consuming and labor-intensive, data entry is prone to errors, ERP systems are out of sync with actual inventory, and inventory information cannot support real-time decision-making... These pain points are being fundamentally addressed through the deep integration of handheld RFID technology with ERP and inventory management systems.

1. The “efficiency bottleneck” of traditional inventory management: Why is integration imperative?

Before system integration, most companies' inventory management processes were a fragmented, closed loop: Warehouse staff, armed with paper receipts or simple barcode scanners, counted and recorded each item individually, then manually entered the data into the inventory management system. Afterward, IT staff regularly exported inventory data, organized it into a fixed format, and imported it into the ERP system for use by procurement, finance, and production departments. This process presented at least three major inefficiencies:

1. Data lag: “Inventory” in ERP is always in the past tense

With manual data entry and periodic synchronization, inventory data in the ERP system often lags behind by hours or even days. For example, a warehouse might ship 500 pieces of raw materials in the morning, but the data isn't entered into the inventory system until the end of the workday, and then synchronized to the ERP system the next day. When the production department uses the ERP data to formulate a daily production plan, they might mistakenly believe that raw materials are in sufficient supply, leading to production interruptions. The purchasing department might also place duplicate orders due to "false inventory," tying up funds.

1. Data lag: “Inventory” in ERP is always in the past tense

With manual data entry and periodic synchronization, inventory data in the ERP system often lags behind by hours or even days. For example, a warehouse might ship 500 pieces of raw materials in the morning, but the data isn't entered into the inventory system until the end of the workday, and then synchronized to the ERP system the next day. When the production department uses the ERP data to formulate a daily production plan, they might mistakenly believe that raw materials are in sufficient supply, leading to production interruptions. The purchasing department might also place duplicate orders due to "false inventory," tying up funds.

2. Human error rate: A 1% error can trigger a chain reaction

Whether it's a counting error during manual inventory counts or a typing error when entering data into a system, even a 1% error rate can have a magnified impact on a company. One retail company once overcounted 200 popular items during inventory, causing the purchasing department to delay restocking and ultimately losing nearly 100,000 yuan in sales due to stockouts. Similarly, in manufacturing, a single incorrect inventory data entry for a component can halt an entire production line.

3. Process fragmentation: Departmental collaboration falls into "information silos"

The inventory management system is responsible for "managing goods" and the ERP system is responsible for "managing processes." When the two are not interoperable, each department can only "sweep the snow in front of its own door": the warehouse is unaware of the production department's urgent material needs, the production department is not clear about the actual available inventory, and the purchasing department cannot adjust orders based on real-time consumption. This "island effect" is the core reason why many companies have coexisting inventory backlogs and stock-outs.

The integration of handheld RFID technology with ERP and inventory systems can break down these barriers: through RFID's "non-contact reading" and "batch identification" capabilities, inventory data can be collected in real time, and then synchronized to ERP through system docking, truly linking "goods, data, and processes."

2. The Core Value of Integration: From “Passive Management” to “Active Control”

The integration of handheld RFID with ERP and inventory management systems is not a simple "technology overlay," but rather a reconstruction of the entire inventory management process through the real-time flow of data. Its value is mainly reflected in four dimensions:

1. Real-time data synchronization: zero delay in inventory data

The core advantage of handheld RFID devices lies in their ability to quickly and accurately collect cargo information. Workers only need to move the device around the warehouse to read dozens or even hundreds of RFID-tagged goods at a time. The collected data will be transmitted to the inventory management system in real time via wireless networks (4G/5G/Wi-Fi). Through preset interfaces (such as APIs and middleware), the inventory system will synchronize the data to the ERP, realizing "data update upon inventory completion."

After implementing an integrated solution, an automotive parts company's monthly inventory count, which previously took three days, now takes only two hours. The discrepancy between inventory data in the ERP system and actual inventory has dropped from 8% to less than 0.5%. The production department can now view the latest parts inventory directly from the ERP system, eliminating the need to send personnel to the warehouse for on-site confirmation. The procurement department can also develop "on-demand" purchasing plans based on real-time consumption data, reducing raw material backlogs by 15%.

2. Reduce manual intervention: Free people from repetitive work

Traditionally, warehouse staff spend 70% of their time doing repetitive tasks: counting inventory, handwriting receipts, and entering data into the system. In an integrated solution, handheld RFID devices automatically identify goods' SKUs, quantities, batches, expiration dates, and other information, eliminating the need for manual judgment and data entry. They can even pre-set "inventory routes," guiding workers along the optimal route to complete the count, avoiding omissions or duplication.

The warehouse manager of an e-commerce company did some calculations: before integration, 10 employees spent 6 hours a day processing inventory data; after integration, 3 employees could complete all the work in 2 hours a day, reducing labor costs by 60%. At the same time, the order mis-delivery rate due to human errors dropped from 3% to 0.1%.

3. Improve decision-making accuracy: Transform ERP from a "bookkeeping tool" to a "decision-making assistant"

The core value of an ERP system lies in integrating a company's financial, procurement, production, and sales data to support management's decision-making. However, if the inventory data in the ERP is not real-time and accurate, its decision-making value will be greatly reduced. With an integrated solution, ERP can obtain dynamic inventory data in real time: which goods are low and need to be replenished? Which goods are overstocked and need promotion? Which batches of goods are about to expire and need priority processing?

A food company's integrated solution enabled its ERP system to automatically alert customers of products approaching expiration, aligning it with the sales department to develop near-expiration promotion plans. It also automatically generated purchase recommendations based on real-time inventory consumption, allowing the purchasing department to simply confirm and place orders. Six months after implementation, the company's inventory turnover days decreased from 45 to 28 days, and the loss rate of near-expiry products dropped from 12% to 3%.

4. Optimize supply chain collaboration: enable upstream and downstream "information exchange"

Inventory isn't isolated; it connects the entire supply chain, from suppliers to businesses and customers. When handheld RFID data is integrated with ERP, businesses can share selected inventory data (such as raw material and finished goods inventory) with suppliers and customers. Suppliers can gain real-time insights into a company's raw material consumption, enabling them to stock up in advance and avoid delivery delays. Customers can use the company's order system to view the inventory status and delivery progress of their purchased products in real time.

A machinery manufacturing company has implemented data sharing with five core suppliers. Through authorized accounts in the ERP system, suppliers can view the company's real-time inventory and consumption rates for related parts. When inventory falls below a preset threshold, suppliers automatically arrange for replenishment. This collaborative model has reduced the company's raw material out-of-stock rate from 18% to 2%, and tripled its supply chain response speed.

III. Key Points for Integrated Implementation: From “Technology Implementation” to “Effectiveness Implementation”

While integrated solutions offer significant value, success isn't simply a matter of "buying equipment and connecting systems." Many companies overlook details during implementation, leading to subpar results. To achieve the transition from "technology implementation" to "realized results," we must focus on three key points:

1. Hardware selection: matching the actual business scenario

When choosing a handheld RFID device, you should not only consider the "high or low parameters", but also consider the company's warehouse environment, cargo type, and frequency of use. For example:

• If the warehouse environment is complex (e.g., with many metal shelves and heavy dust), you need to choose industrial-grade equipment with strong anti-interference capabilities and high durability to avoid interference with the reading signal;

• If the goods are small parts (such as electronic components), you need to choose "high-frequency RFID equipment" to ensure accurate recognition of small-sized tags;

• If the warehouse is large and workers need to work on the move, it is necessary to choose a device with "long battery life" (at least 8 hours) and "support for 4G network" to avoid power outages or network disconnections.

In addition, device compatibility is also very important - it is necessary to ensure that the handheld RFID device can interface with the company's existing inventory management system and ERP system (such as SAP, UFIDA, Kingdee, etc.) to avoid data transmission failure due to "system incompatibility".

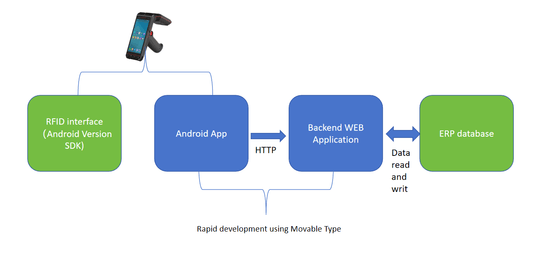

2. Software integration: Building a “data bridge”

The core of system integration is "data interoperability", and software docking is the "bridge" to achieve interoperability. There are two common docking methods:

• API interface connection : Through the standard API provided by the ERP system and inventory management system, a data transmission channel is directly established. This method has a fast response speed and high real-time data, which is suitable for most enterprises.

• Middleware docking : If the interfaces of the two systems are incompatible, middleware (such as IBM MQ and Apache Kafka) can be used as a "transfer station" to first transmit the data collected by RFID to the middleware, and then the middleware will organize the format and synchronize it to the two systems. This method is highly flexible and suitable for complex system environments.

Regardless of which method you choose, you need to pay attention to "data security" - you need to set up data transmission encryption (such as SSL encryption) and access permission control (such as different departments can only view corresponding data) to prevent inventory data from being leaked or tampered with.

3. Personnel training: Helping employees move from “resistance” to “adaptation”

The final step in implementing technology is human adaptation. Many warehouse staff are accustomed to manual inventory taking and may be resistant to new equipment and processes. Therefore, companies need to provide training in two areas:

• Operational training : Provide hands-on instruction on the use of handheld RFID devices (such as powering on, reading, and uploading data) and handling abnormal situations (such as reading failures and device malfunctions) to ensure that employees can operate independently.

• Concept training : Help employees understand the benefits of the integrated solution—such as reduced overtime, lower work error rates, and even improved personal efficiency assessments—to shift from passive acceptance to active participation.

When implementing this policy, a logistics company first selected a small warehouse as a "pilot," allowing employees to personally experience the efficiency improvement of "completing inventory in 2 hours." It then gradually expanded the policy to other warehouses, ultimately achieving employee acceptance of over 90%.

IV. Future Outlook: From “Automation” to “Intelligence”

With the development of the Internet of Things and artificial intelligence technologies, the integration of handheld RFID with ERP and inventory systems will usher in more room for upgrading:

• AI inventory forecasting : By analyzing historical inventory data, sales data, and market demand, it automatically predicts future inventory needs and provides early warning of "out-of-stock risks" or "overstock risks";

• Unmanned inventory counting : Combined with drones and AGV robots, "unmanned" inventory counting is achieved, and staff only need to check the data in the background;

• Full-link traceability : RFID tags record the entire chain of information on goods, from production to storage to shipment to transportation and delivery. Once a problem occurs, the source can be quickly traced.

For enterprises, the most important thing at the moment is not to wait for "more advanced technology", but to grasp the core of "integration" - through the linkage of handheld RFID with ERP and inventory systems, first solve the pain points of "data asynchrony and low manual efficiency" and lay the foundation for future intelligent upgrades.

Conclusion

The essence of inventory management is data management—the more up-to-date and accurate the data, the higher the management efficiency. The integration of handheld RFID with ERP and inventory management systems, through "real-time data collection + system linkage," breaks down the barriers of traditional inventory management, enabling companies to shift from passively responding to inventory issues to proactively controlling inventory efficiency.

For companies still struggling with inventory issues, it's worth asking yourself three questions: Is the inventory data in your ERP reliable? Is warehouse inventory efficient enough? Does inventory information adequately support decision-making? If the answer is no, then integration may be the first step to resolving the problem.

No comments

0 comments