Warehouse Efficiency Boost: Real-World Success Stories with Handheld RFID

Introduction

In today’s fast-paced logistics and supply chain industry, warehouse efficiency is a critical factor in staying competitive. Manual inventory tracking, misplaced stock, and delayed shipments can lead to significant losses. However, Radio Frequency Identification (RFID) technology, especially when combined with handheld RFID readers, is transforming warehouse operations by enabling real-time tracking, reducing errors, and improving overall productivity.

This blog explores real-world success stories of companies that have boosted warehouse efficiency using handheld RFID. We’ll also introduce the LS-N41U RFID Handheld Mobile Computer, a powerful tool designed for modern warehouse management.

The Challenges of Traditional Warehouse Management

Before diving into RFID success stories, let’s examine the common pain points in warehouse operations:

-

Time-Consuming Manual Scanning – Barcode systems require line-of-sight scanning, slowing down inventory checks.

-

Human Errors in Data Entry – Manual logging leads to mistakes in stock counts and order fulfillment.

-

Lost or Misplaced Inventory – Without real-time tracking, items can go missing, causing delays and stock discrepancies.

-

Inefficient Picking & Packing – Workers waste time searching for items, reducing order fulfillment speed.

-

High Labor Costs – Excessive manpower is needed for repetitive inventory checks.

These challenges highlight why many warehouses are turning to handheld RFID solutions for automation and accuracy.

How Handheld RFID Improves Warehouse Efficiency

RFID technology uses radio waves to identify and track tagged items automatically, eliminating the need for direct scanning. Here’s how it enhances warehouse operations:

1. Faster Inventory Management

-

Traditional barcode scanning requires workers to scan each item individually.

-

RFID enables bulk scanning—hundreds of tagged items can be read in seconds without direct visibility.

2. Real-Time Stock Visibility

-

RFID provides live updates on inventory levels, reducing stockouts and overstocking.

-

Warehouse managers can make data-driven decisions instantly.

3. Reduced Picking Errors

-

RFID-guided picking systems direct workers to exact item locations, minimizing mistakes.

-

Some systems even confirm picked items before packing, ensuring order accuracy.

4. Theft and Loss Prevention

-

High-value goods can be tracked throughout the warehouse, deterring theft.

-

Alerts can be set up if items leave unauthorized zones.

5. Seamless Integration with WMS

-

RFID data syncs with Warehouse Management Systems (WMS), automating workflows like reordering and restocking.

Real-World Success Stories

Case Study 1: Retail Giant Cuts Inventory Time by 90%

A leading US retail chain struggled with slow inventory checks, taking weeks to complete manual stock audits. After deploying handheld RFID readers, they reduced inventory counting time from 3 weeks to just 2 days—a 90% improvement.

Key Benefits:

✔ Faster stock reconciliation

✔ Fewer discrepancies

✔ Reduced labor costs

Case Study 2: E-Commerce Fulfillment Center Boosts Picking Speed

An Asian e-commerce warehouse faced delays in order processing due to inefficient picking. By implementing RFID-guided picking systems, they increased picking speed by 40% and reduced mispicks by 95%.

Key Benefits:

✔ Higher order accuracy

✔ Faster same-day shipping

✔ Lower return rates

Case Study 3: Automotive Parts Supplier Eliminates Stockouts

A European auto parts distributor frequently faced stockouts due to poor inventory visibility. After tagging all items with UHF RFID, they achieved 99.9% inventory accuracy and eliminated stockouts.

Key Benefits:

✔ Just-in-time inventory management

✔ Reduced carrying costs

✔ Improved supplier relations

Introducing the LS-N41U RFID Handheld Mobile Computer

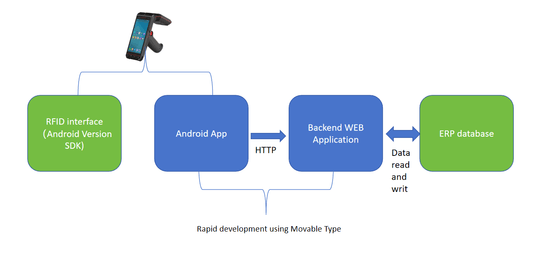

To maximize RFID benefits, warehouses need a rugged, high-performance handheld RFID reader. The LS-N41U RFID Handheld Mobile Computer is an ideal solution for modern logistics challenges.

Key Features:

✔ Long-Range UHF RFID Scanning – Reads tags from up to 10 meters for bulk inventory checks.

✔ Android OS with Custom Apps – Supports warehouse management software for seamless integration.

✔ Rugged & Drop-Resistant – Built for tough warehouse environments (IP67 rating).

✔ Barcode & RFID Hybrid Scanning – Works with both RFID and traditional barcodes.

✔ Long Battery Life – Ensures uninterrupted operation during long shifts.

Applications in Warehousing:

-

Automated Inventory Audits – Scan hundreds of items in minutes.

-

Smart Picking & Packing – Reduce errors with RFID-guided workflows.

-

Asset Tracking – Monitor high-value equipment and pallets.

-

Shipping & Receiving – Verify inbound/outbound shipments instantly.

Conclusion

Handheld RFID is no longer a luxury—it’s a necessity for warehouses aiming to cut costs, improve accuracy, and speed up operations. As seen in real-world cases, companies using RFID achieve:

✅ 90% faster inventory checks

✅ 40% higher picking efficiency

✅ Near-perfect stock accuracy

The LS-N41U RFID Handheld Mobile Computer is a powerful tool that brings these benefits to any warehouse. By adopting RFID technology, businesses can future-proof their logistics operations and stay ahead in the competitive supply chain industry.

Is your warehouse ready for an RFID upgrade? Let us know your biggest inventory challenge in the comments! �

Would you like a free consultation on implementing RFID in your warehouse? Contact us today! 🚀

No comments

0 comments