RFID vs Barcode: Which is Right for Your Factory?

In today's fast-paced manufacturing environment, efficient asset tracking and inventory management are critical for maintaining productivity and reducing operational costs. Two of the most common technologies used for this purpose are Radio Frequency Identification (RFID) and barcodes. While both serve similar purposes, they differ significantly in their capabilities, costs, and suitability for different factory environments.

This comprehensive guide will compare RFID and barcode technologies across various parameters to help you determine which solution—or combination of solutions—is right for your manufacturing facility.

Understanding the Technologies

What is Barcode Technology?

Barcodes are visual representations of data that consist of parallel lines (1D barcodes) or patterns of squares, dots, and other shapes (2D barcodes like QR codes). They require a direct line of sight to be read by optical scanners.

How it works:

-

Information is encoded into a barcode symbol

-

A barcode scanner uses light to read the pattern

-

The pattern is decoded back into the original information

What is RFID Technology?

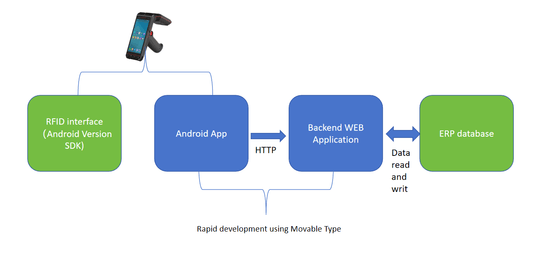

RFID uses radio waves to automatically identify objects without requiring a direct line of sight. An RFID system consists of tags (which contain electronically stored information) and readers (which retrieve the information).

How it works:

-

RFID tags contain a microchip and antenna

-

RFID readers emit radio waves

-

Tags within range respond with their stored data

Key Comparison Factors

1. Read Speed and Efficiency

Barcode:

-

Requires manual scanning of each item

-

Typically processes 1-2 items per second

-

Slower for bulk scanning operations

RFID:

-

Can read multiple items simultaneously (up to hundreds per second)

-

No need to position items precisely

-

Much faster for inventory counts and bulk operations

Factory Impact: RFID dramatically reduces time spent on inventory management, especially in large facilities with high-volume production.

2. Line of Sight Requirements

Barcode:

-

Requires direct line of sight

-

Barcode must be visible and unobstructed

-

Scanning angle is limited

RFID:

-

No line of sight needed

-

Can read tags through packaging, containers, and even some materials

-

Tags can be hidden or embedded

Factory Impact: RFID enables more flexible tag placement and can read items in difficult positions or inside containers, reducing handling time.

3. Data Capacity and Flexibility

Barcode:

-

1D barcodes: 20-25 characters

-

2D barcodes: up to 2,000 characters

-

Data is fixed at printing

RFID:

-

Typically 96 bits to 8KB of data

-

Data can be rewritten or updated

-

Can store more detailed information

Factory Impact: RFID allows for dynamic data updates (like maintenance history) and more detailed tracking information without needing to reprint labels.

4. Read Range

Barcode:

-

Typically inches to a few feet

-

Depends on scanner type and barcode quality

RFID:

-

Passive tags: up to 10 meters (UHF)

-

Active tags: 100+ meters

-

Depends on frequency and tag type

Factory Impact: Longer read ranges enable automated tracking through portals and at greater distances, useful for large facilities.

5. Durability and Environment

Barcode:

-

Vulnerable to damage (tears, smudges, fading)

-

Performance affected by dirt, moisture, and harsh conditions

-

Limited lifespan

RFID:

-

More resistant to harsh environments

-

Can be encased in protective materials

-

Generally more durable long-term

Factory Impact: RFID performs better in dirty, wet, or extreme temperature environments common in many factories.

6. Cost Considerations

Barcode:

-

Very low cost per label ($0.01-$0.10)

-

Scanners: $100-$1,000

-

Minimal infrastructure needed

RFID:

-

Tags: $0.10-$50 depending on type

-

Readers: $500-$5,000

-

May require additional infrastructure

Factory Impact: While RFID has higher upfront costs, the long-term labor savings and efficiency gains often justify the investment for many operations.

7. Integration with Existing Systems

Barcode:

-

Simple to implement

-

Widely supported by existing software

-

Minimal training required

RFID:

-

Requires more sophisticated integration

-

May need middleware for data processing

-

Staff may need additional training

Factory Impact: Barcodes offer easier adoption, while RFID may require more planning but enables more advanced capabilities.

Industry-Specific Considerations

Automotive Manufacturing

RFID excels for tracking parts through complex assembly processes where items move quickly and visibility is limited. The ability to withstand harsh paint shop environments is particularly valuable.

Food and Beverage

Barcodes often suffice for basic tracking needs in food production, though RFID can help with temperature monitoring when integrated with sensors.

Electronics Manufacturing

RFID's ability to store detailed component histories and withstand ESD-sensitive environments makes it ideal for high-value electronics production.

Heavy Industry

RFID's durability makes it better suited for tracking large equipment and tools in harsh industrial environments where barcodes might degrade quickly.

Hybrid Solutions: Getting the Best of Both Worlds

Many factories find value in implementing both technologies:

-

Use barcodes for low-value, high-volume items

-

Implement RFID for high-value assets, tools, and WIP tracking

-

Combine technologies where appropriate (RFID for bulk scanning, barcodes for verification)

Implementation Roadmap

For Barcode Systems:

-

Assess labeling requirements

-

Select appropriate barcode type (1D vs 2D)

-

Choose durable labels for your environment

-

Select scanners suited to your use case

-

Train staff on proper scanning techniques

For RFID Systems:

-

Conduct a thorough site assessment

-

Choose appropriate frequency (LF, HF, or UHF)

-

Select tag types based on materials and environment

-

Design reader placement for optimal coverage

-

Implement middleware for data processing

-

Train staff on system operation

Future Trends

-

Cost Reduction: RFID tag prices continue to decline, making the technology more accessible

-

Sensor Integration: Smart RFID tags with environmental sensors are becoming more common

-

AI Integration: Both technologies are being enhanced with AI for better data analysis

-

Printed Electronics: Development of printed RFID tags could further reduce costs

Conclusion: Making the Right Choice for Your Factory

The decision between RFID and barcode technology depends on multiple factors:

Choose Barcodes If:

-

Your tracking needs are simple

-

Items are easily accessible for scanning

-

You have budget constraints

-

Your environment isn't overly harsh

Choose RFID If:

-

You need to track large volumes quickly

-

Items are hard to access or view directly

-

You need advanced data capabilities

-

The environment is challenging for labels

-

The ROI justifies the higher initial cost

For many modern factories, a combination approach provides the optimal balance between cost and capability. Start by analyzing your specific operational requirements, then pilot the technology in a controlled area before full-scale implementation.

Remember that the right tracking system should:

-

Improve operational efficiency

-

Reduce errors

-

Provide actionable data

-

Scale with your business

-

Deliver a clear return on investment

By carefully evaluating RFID and barcode technologies against your specific needs, you can implement a tracking solution that enhances visibility, improves efficiency, and supports your factory's growth for years to come.

No comments

0 comments