The Role of PDAs in Ensuring Effective Vaccine Cold Chain Monitoring

The success of vaccination programs heavily depends on maintaining the integrity of vaccines throughout the supply chain—from manufacturing to administration. Vaccines are highly sensitive to temperature fluctuations, and exposure to improper storage conditions can render them ineffective. This is where the cold chain comes into play—a temperature-controlled supply chain that ensures vaccines remain within the recommended temperature range (typically 2°C to 8°C for most vaccines).

One of the most critical tools in modern cold chain management is the Personal Digital Assistant (PDA). These handheld devices have evolved beyond simple data collection tools and now play a vital role in real-time temperature monitoring, inventory management, and compliance reporting. In this blog, we will explore how PDAs enhance vaccine cold chain monitoring, their key features, benefits, and future trends.

Why Cold Chain Monitoring is Crucial for Vaccines

Vaccines must be stored at precise temperatures to maintain their efficacy. If exposed to temperatures outside the recommended range:

-

Potency Loss: The vaccine may lose its ability to provide immunity.

-

Wastage: Millions of dollars are lost annually due to spoiled vaccines.

-

Public Health Risks: Ineffective vaccines can lead to outbreaks of preventable diseases.

Traditional cold chain monitoring relied on manual temperature logs, which were prone to human error and lacked real-time alerts. PDAs have revolutionized this process by enabling automated, accurate, and real-time monitoring.

How PDAs Enhance Vaccine Cold Chain Monitoring

1. Real-Time Temperature Tracking

Modern PDAs are equipped with integrated temperature sensors or can connect to external Bluetooth-enabled data loggers. These devices continuously monitor storage conditions and send alerts if temperatures deviate from the safe range.

Key Advantages:

-

Immediate notifications via SMS or email if a freezer malfunctions.

-

Historical temperature data for compliance audits.

-

Reduced dependency on manual checks.

2. Inventory Management

PDAs with barcode or RFID scanning capabilities help track vaccine stock levels, expiry dates, and batch numbers. This prevents:

-

Stockouts: Ensures vaccines are available when needed.

-

Expired Vaccines: Alerts staff before vaccines reach their expiry date.

-

Efficient Distribution: Optimizes vaccine allocation based on demand.

3. Digital Record-Keeping & Compliance

Regulatory bodies (such as WHO, CDC, and FDA) require strict documentation of vaccine storage conditions. PDAs automate this process by:

-

Generating digital logs that cannot be tampered with.

-

Providing audit-ready reports for inspections.

-

Ensuring compliance with Good Distribution Practices (GDP).

4. GPS & Geolocation Tracking

For vaccines transported via trucks or drones, PDAs with GPS can:

-

Track shipment locations in real time.

-

Ensure vaccines are not exposed to extreme temperatures during transit.

-

Provide route optimization to minimize delays.

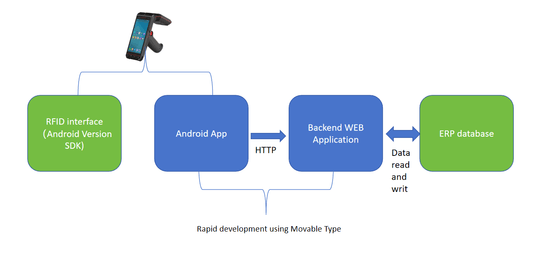

5. Integration with Cloud-Based Systems

Many PDAs sync data with cloud platforms, allowing:

-

Centralized Monitoring: Health authorities can oversee multiple storage facilities remotely.

-

Predictive Analytics: AI can analyze trends to predict equipment failures before they occur.

-

Seamless Reporting: Automated data sharing with government health agencies.

Case Study: PDA Use in COVID-19 Vaccine Distribution

During the COVID-19 pandemic, the rapid distribution of Pfizer-BioNTech and Moderna vaccines—which required ultra-cold storage (−70°C for Pfizer)—highlighted the need for advanced cold chain monitoring. Many countries and organizations deployed PDAs to:

-

Monitor ultra-low temperature freezers.

-

Track vaccine batches in real time.

-

Ensure equitable distribution to rural and urban centers.

Result: Reduced vaccine wastage and improved public trust in immunization programs.

Challenges and Solutions in PDA-Based Cold Chain Monitoring

1. Battery Life & Durability

-

Challenge: PDAs used in remote areas must have long battery life.

-

Solution: Rugged PDAs with extended battery options and solar charging capabilities.

2. Connectivity Issues in Remote Areas

-

Challenge: Poor internet access can delay real-time alerts.

-

Solution: Offline data storage with automatic sync when connectivity is restored.

3. High Initial Costs

-

Challenge: Small clinics may find PDAs expensive.

-

Solution: Government subsidies or leasing models to improve accessibility.

Future Trends in PDA-Based Cold Chain Monitoring

1. AI-Powered Predictive Maintenance

-

AI algorithms will predict freezer failures before they happen, reducing spoilage risks.

2. Blockchain for Tamper-Proof Records

-

Blockchain integration will ensure immutable temperature logs, enhancing transparency.

3. IoT-Enabled Smart Freezers

-

PDAs will communicate with IoT-enabled refrigerators for fully automated monitoring.

4. Expansion to Low-Income Countries

-

Affordable PDA solutions will help improve vaccine coverage in developing nations.

Conclusion

PDAs have become indispensable in vaccine cold chain monitoring, offering real-time tracking, automated alerts, and digital compliance reporting. As technology advances, their role will expand further, ensuring that life-saving vaccines reach patients in optimal condition. Governments, healthcare providers, and logistics companies must continue investing in PDA-based solutions to strengthen global immunization efforts.

By leveraging these smart devices, we can minimize vaccine wastage, enhance public health outcomes, and build a more resilient cold chain for future pandemics.

What are your thoughts on PDA use in vaccine distribution? Have you seen these technologies in action? Share your experiences in the comments!

No comments

0 comments