The Ultimate Guide to Choosing a Rugged PDA Terminal for Cold Storage Environments

Selecting the perfect rugged PDAs for your cold storage facility is a key decision impacting workflow efficiency, accuracy, and device longevity. Discover how to tackle the challenges of frigid environments, maintain productivity, and ensure your team always stays connected—no matter how low the temperature drops.

Understanding Cold Storage Challenges

Cold storage facilities are unique workspaces that pose specific operational difficulties. From freezing temperatures to moisture accumulation, these challenging environments can damage standard electronics and hamper staff productivity if the wrong tools are used.

- Extreme Low Temperatures: Standard devices fail quickly below freezing, leading to screen malfunction, battery drain, and internal condensation.

- Frequent Temperature Fluctuations: Moving between cold and ambient areas causes condensation, threatening device internals.

- Moisture and Frost Accumulation: High humidity and frost can impair touchscreens and electronic ports.

- Physical Hazards: Devices must withstand accidental drops onto hard floors, bumping, and general wear and tear.

Navigating these hazards with unsuitable hardware can lead to workflow delays, inaccurate data logging, and high annual device replacement costs. That’s where a rugged PDA, designed specifically for adverse conditions, proves invaluable.

What Is a Rugged PDA and Why Is It Essential?

A rugged PDA, or Personal Digital Assistant, is a handheld computing device engineered to operate reliably in the harshest industrial environments. Unlike consumer tablets or smartphones, rugged PDAs offer robust physical protection, thermal insulation, and advanced connectivity tailored for fieldwork.

Rugged PDA: The Linchpin of Cold Storage Operations

Typical applications within cold storage warehouses include:

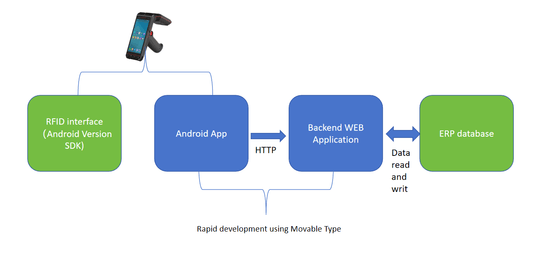

- Inventory tracking with barcode or RFID

- Order picking and fulfillment automation

- Real-time temperature readings

- Voice and text communication

Without a specialized rugged PDA, operators could face device downtimes and data loss—leading to costly bottlenecks.

Key Features to Look For in a Rugged PDA for Cold Storage

Choosing the right rugged PDA is crucial to maintaining uninterrupted workflow and device lifespan. Here’s what to prioritize:

1. Cold-Resistant Battery Technology

Batteries often falter in low temperatures. Seek devices equipped with batteries rated for subzero conditions, often featuring:

- Heated battery compartments

- Extended battery life in the cold

- Hot-swappable modules for continuous use

This feature helps avoid sudden device shutdowns, keeping operations running without pause.

2. Screen Readability and Touch Sensitivity

Operating in low light or through thick gloves requires special display features. The best rugged PDA for cold storage offers:

- Bright, high-contrast screens for dim or glare-prone areas

- Glove-friendly multi-touch

- Displays that remain responsive in freezing and humid settings

Look for chemical or anti-fog coatings, preventing vision impairment from condensation.

3. Industrial-Grade Durability

A rugged PDA must survive more than the cold. Prioritize models with:

- Drop resistance(1.5m drop test approved)

- Sealed housing rated to at least IP65 or higher for water and dust protection

- Reinforced casings resisting shocks, bumps, and impacts

For environments where forklifts and pallets are common, this resilience is essential.

4. Data Capture Capabilities

Select a PDA capable of advanced, fast data collection:

- Integrated high-performance barcode scanner (1D/2D imaging)

- Optional RFID or NFC modules for asset tracking

- Fast autofocus camera for documentation

Efficient data capture reduces pick errors and speeds up every stage of warehouse management.

5. Broad Wireless and Connectivity Options

Stable connections are key for real-time updates and inventory tracking. You’ll want:

- Dual-band Wi-Fi for robust, uninterrupted connectivity

- Bluetooth for peripheral and headset pairing

- Optional cellular/4G LTE if needed for remote communication

Wireless stability ensures staff are always connected to your inventory system.

6. Programmable Physical Keys

Gloved or wet hands don’t always suit touchscreens. A rugged PDA with customizable hardware buttons allows for:

- Quick action shortcuts in low-dexterity situations

- Reliable use in subzero and high-moisture scenarios

This practical design tweak can greatly speed up repetitive warehouse tasks.

7. Operating System and Software Support

Compatibility with your warehouse management system (WMS) matters. Today’s leading rugged PDAs commonly run:

- Android OS, with security patches and device management

- Windows-based systems for certain legacy integrations

Ensure ongoing support, updates, and app compatibility for your chosen platform.

Evaluating Device Performance in Subzero Conditions

Not all rugged PDAs are built equal—especially when it comes to frigid storage environments. But how do you determine whether a device will truly withstand daily use in such temperatures?

Environmental-Grade Certifications

Industry-standard certifications help verify device ruggedness. Look for:

- IP65, IP67, or IP68 ratings for water and dust ingress

- MIL-STD-810G or 810H (US military standards) for shock, vibration, temperature, and humidity resistance

- Verified operational temperature ranges (e.g., -20°C to +50°C or lower)

Real-World User Feedback

Seek out reliable case studies or user testimonials from cold storage settings. Peer insights can reveal potential weak points—or unexpected advantages—not always listed in product specs.

Battery Endurance Testing

Assess real battery life in your intended environment. Some devices that boast “all-day battery” under normal temperatures may dramatically underperform below zero.

Additional Considerations for Your Cold Storage Rugged PDA

Beyond the basics, optimizing device deployment and maintenance ensures maximum return on investment.

Maintenance and Serviceability

Frequent use in harsh settings means maintenance is often necessary. Devices that offer:

- Easy access to replaceable batteries, screens, or key modules

- Onsite or depot-level repair programs

- Swappable components to minimize downtime

reduce the total cost of ownership over time.

Device Accessories

Multiplying the functionality and comfort of your rugged PDA can be achieved with accessories like:

- Freezer-grade carrying holsters or harnesses

- External battery chargers and powered cradles

- Vehicle docks for forklifts, ensuring constant charging during shifts

- Spare batteries labeled for cold usage

The right add-ons allow staff to use PDAs efficiently in every cold storage scenario.

Integration with Warehouse Systems

Your rugged PDA should integrate smoothly with inventory tools, picking software, and temperature control systems. Test compatibility by:

- Running trials with your existing WMS software

- Checking for compatible APIs and plug-ins

- Ensuring real-time data sync without lag or errors

A seamless fit avoids future integration headaches and boosts team productivity from the start.

Rugged PDA Selection Checklist for Cold Storage

Summing up, here’s a handy list to review before finalizing your rugged PDA purchase for frozen or refrigerated environments:

- Temperature resistance: Certified to function in your facility’s coldest areas.

- Battery life: Rated for extended use in subzero temperatures; swappable options for multi-shift coverage.

- Display: Bright, glove-friendly, fog- and condensation-resistant.

- Protection: Drop-tested, sealed against water and dust.

- Data collection: Fast, accurate barcode scanner; consider RFID needs.

- Connectivity: Dual-band Wi-Fi, Bluetooth, optional LTE.

- Physical buttons: Programmable for gloved operation.

- Software: Compatible with current and upcoming systems.

- Accessories: Holsters, chargers, vehicle docks for workflow optimization.

- Serviceability: Easy access for repairs and battery swaps.

Best Practices for Deploying Rugged PDAs in Cold Storage

Even the best rugged PDA can underperform if deployed without proper planning. Achieve maximum efficiency with these best practices:

- Pilot before rollout: Test selected units in the coldest, busiest sections of your site.

- Train staff: Teach users the features and optimal handling of rugged PDAs, especially battery management and condensation prevention.

- Routine maintenance: Schedule regular cleanings, updates, and battery checks.

- Monitor performance: Track device uptime, Wi-Fi signal strength, and scanning reliability for early problem detection.

- Prepare for upgrades: Industrial demands evolve—stay informed on firmware and software updates that enable new features or improve stability.

A focused rollout plan saves both time and money, ensuring your chosen rugged PDA keeps working shift after shift.

Future-Proofing Your Cold Storage Operations

Technology in cold chain logistics is advancing quickly. Today’s rugged PDAs offer features that anticipate tomorrow’s warehouse needs:

- IoT readiness: Some models natively connect to IoT sensors or beacons, expanding asset and temperature tracking possibilities.

- Advanced imaging: Faster AI-based barcode readers and image recognition speed up labeling and documentation.

- Enhanced security: Biometric authentication and multi-factor logins protect sensitive inventory data.

- Remote management tools: Over-the-air updates and diagnostics simplify device management, minimizing IT intervention.

Investing in a future-ready rugged PDA, rather than the bare minimum, will help your operation stay competitive as logistics technology evolves.

Common Pitfalls to Avoid When Choosing a Rugged PDA

Awareness of typical selection mistakes can save significant time and money. The following pitfalls frequently impact decision-makers:

- Ignoring temperature specifications: A device labeled “rugged” may still fail in freezing temps.

- Overlooking battery performance: Long theoretical runtime can equate to short real-world operation below zero.

- Assuming all screens are glove-friendly: Always test interface usability with gloved hands and in foggy environments.

- Skipping software trials: Hardware compatibility alone isn’t enough; integrate with warehouse software before full-scale purchase.

- Neglecting after-sales support: Without local repair or quick-swap services, device downtime is inevitable.

Careful assessment helps you avoid the headaches and costs of replacement or retrofitting down the line.

Frequently Asked Questions about Rugged PDAs in Cold Storage

Are all rugged PDAs suitable for cold storage use?

Not necessarily. Many rugged PDAs are intended for general industrial environments but lack the cold resistance and battery resilience required for subfreezing operations. Always confirm a unit’s certified temperature range and user field reports.

Can rugged PDAs help with traceability in the cold chain?

Yes. By enabling staff to scan barcodes or RFID tags rapidly and log time-stamped data in real-time, rugged PDAs enhance product traceability from entry to exit, even in deep freeze conditions.

How long will a rugged PDA last in cold storage environments?

With proper maintenance, regular cleaning, timely battery changes, and expert deployment, a quality rugged PDA should last several years—far exceeding consumer device lifespans in similar conditions.

Conclusion

Finding the right rugged PDA is a cornerstone of effective cold storage operations. By focusing on cold resistance, durability, seamless integration, and real-world usability, you ensure your team stays productive and your data stays secure—no matter how icy it gets. Evaluate thoroughly and invest wisely for lasting results in your warehouse.

No comments

0 comments