RFID vs Barcode: Which is Better for Warehouses? (2024 Comparison)

In today's fast-moving logistics environment, warehouse managers face a critical decision: Should you use RFID or barcode technology for inventory tracking? Both have advantages, but choosing the right system can mean the difference between efficient operations and costly inefficiencies.

This comprehensive guide compares:

✅ How RFID and barcodes work in warehouse environments

✅ Key differences in speed, accuracy, and cost

✅ Industry-specific recommendations

✅ Implementation considerations

✅ Future trends in warehouse tracking

By the end, you'll know exactly which technology (or combination) best fits your warehouse needs.

1. How Barcode and RFID Systems Work in Warehouses

Barcode Technology

-

Uses laser/optical scanners to read black-and-white patterns

-

Requires direct line-of-sight for scanning

-

Typically stores only product ID numbers

-

Most common types:

-

1D barcodes (UPC, EAN) - Simple product identification

-

2D QR codes - Can store more data (100+ characters)

-

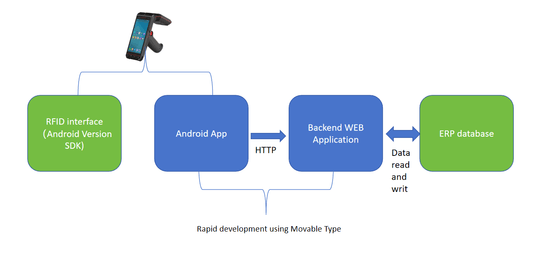

RFID Technology

-

Uses radio waves to communicate with tags

-

No line-of-sight needed (reads through packaging)

-

Can store extensive data (serial numbers, maintenance history)

-

Main frequency types:

-

UHF RFID (Ultra-High Frequency) - Best for warehouse pallet/case tracking (5-12m range)

-

HF RFID (High Frequency) - Better for item-level tagging (near-field)

-

2. Head-to-Head Comparison: RFID vs Barcodes

| Feature | Barcodes | RFID |

|---|---|---|

| Scanning Speed | 1-2 items/sec | 100+ items/sec |

| Read Range | Inches | Up to 12m (UHF) |

| Line-of-Sight | Required | Not required |

| Data Capacity | Limited (ID only) | Extensive (rewritable) |

| Durability | Easily damaged | Rugged (water/dust proof) |

| Cost per Tag | $0.01-$0.10 | $0.10-$5.00 |

| Scanner Cost | $50-$500 | $500-$3,000 |

| Metal/Liquid Interference | None | Can cause issues |

3. When to Choose Barcodes for Your Warehouse

Best For:

✔ Small warehouses with limited budgets

✔ Operations with simple SKU tracking needs

✔ Environments with metal/liquid products (no RFID interference)

✔ Businesses with existing barcode infrastructure

Advantages:

-

Extremely low cost to implement

-

Universal compatibility with all WMS systems

-

Easy to print new labels on-demand

Use Cases:

-

Retail backrooms with small inventory

-

Pharmaceutical storage (bottle-level tracking)

-

Warehouses with mostly manual processes

4. When RFID is the Better Choice

Best For:

✔ Large distribution centers with high-volume scanning

✔ Operations needing real-time inventory visibility

✔ Cold storage/outdoor warehouses (durable tags)

✔ High-value goods requiring anti-theft protection

Advantages:

-

20x faster scanning than barcodes

-

Automated inventory counts (no manual scanning)

-

Tamper-evident tags for security

-

Sensor-enabled tags (temperature, shock monitoring)

Use Cases:

-

E-commerce fulfillment centers

-

Automotive parts warehouses

-

Food/beverage cold chain logistics

5. Hybrid Approach: Using Both Technologies

Many modern warehouses combine RFID for bulk scanning and barcodes for final verification:

Example Workflow:

-

RFID portals automatically scan entire pallets at receiving

-

Barcode scanners verify individual items during picking

-

RFID gates confirm outbound shipments

Benefits:

-

Leverages RFID's speed for bulk operations

-

Maintains barcode's precision for critical checks

-

Phased implementation reduces risk

6. Cost Comparison: ROI Analysis

| Factor | Barcodes | RFID |

|---|---|---|

| Implementation Cost | $1,000-$10,000 | $50,000-$500,000+ |

| Tag Cost | $0.01-$0.10 | $0.10-$5.00 |

| Labor Savings | Minimal | 30-70% reduction |

| Error Reduction | 10-20% | 50-90% |

| Payback Period | Immediate | 1-3 years |

Key Insight:

While RFID has higher upfront costs, large warehouses typically see ROI within 18 months through labor savings and reduced shrinkage.

7. Implementation Challenges

Barcode Limitations:

-

Slow for bulk scanning (must scan items individually)

-

Labels degrade in harsh environments

-

No real-time visibility between scans

RFID Challenges:

-

Metal/liquid interference requires special tags

-

Reader collision in dense tag environments

-

Higher IT complexity for system integration

8. Future Trends: What's Next for Warehouse Tracking?

-

Computer Vision + RFID: AI cameras complement RFID for 100% accuracy

-

Smart Shelves: RFID-enabled racks with weight sensors

-

Blockchain Integration: Tamper-proof supply chain records

9. Making the Right Choice for Your Warehouse

Choose Barcodes If:

-

You have limited budget

-

Your SKU complexity is low

-

You already have barcode infrastructure

Choose RFID If:

-

You move high volumes daily

-

You need real-time inventory visibility

-

You track high-value or regulated goods

Consider Hybrid If:

-

You want to phase in automation

-

You have mixed scanning needs

10. Leeshion's Warehouse Tracking Solutions

For operations ready to upgrade, the Leeshion LS-N41U UHF RFID Terminal offers:

✔ 10m read range for pallet/case tracking

✔ Android OS for easy WMS integration

✔ IP67 ruggedness for demanding environments

Perfect for:

-

Automated receiving/shipping

-

Cycle counting

-

Yard management

👉 Learn about our RFID solutions

Conclusion

While barcodes remain cost-effective for simple operations, RFID delivers unmatched efficiency for high-volume warehouses. The best choice depends on your:

-

Budget

-

Volume needs

-

Accuracy requirements

Still unsure? Contact our experts for a free warehouse assessment.

🔗 Further Reading:

Ready to optimize your inventory tracking? Get a consultation today!

No comments

0 comments