How to Implement RFID in Manufacturing: A Step-by-Step Guide (2025)

The manufacturing industry thrives on efficiency, accuracy, and real-time visibility. RFID (Radio Frequency Identification) technology has emerged as a game-changer, enabling automated tracking of raw materials, work-in-progress (WIP), tools, and finished goods.

But how do you successfully implement RFID in your manufacturing plant?

This step-by-step guide covers:

✅ Benefits of RFID in manufacturing

✅ Planning your RFID deployment

✅ Choosing the right hardware & software

✅ Installation and integration best practices

✅ Real-world case studies

By the end, you’ll have a clear roadmap to reduce errors, improve inventory accuracy, and boost productivity with RFID.

1. Why RFID in Manufacturing? Key Benefits

| Pain Point | RFID Solution | ROI Impact |

|---|---|---|

| Manual inventory tracking errors | Automated real-time tracking | 30-50% faster audits |

| Lost/misplaced tools & equipment | RFID-tagged asset tracking | 20% reduction in equipment loss |

| Work-in-progress bottlenecks | Automated WIP tracking | 15-25% faster production cycles |

| Counterfeit parts in supply chain | Secure RFID authentication | Reduced recalls & warranty costs |

Additional Benefits:

✔ Reduced labor costs (less manual scanning)

✔ Improved compliance (automated record-keeping)

✔ Enhanced predictive maintenance (sensor-enabled RFID tags)

2. Step-by-Step RFID Implementation Plan

Ask:

-

What are you tracking? (Materials, WIP, tools, finished goods)

-

What problems are you solving? (Inventory inaccuracies? Lost assets?)

-

What’s your budget? (Pilot vs. full-scale deployment)

Example Use Cases:

-

Automotive: Tracking engine components through assembly

-

Electronics: Preventing counterfeit parts in the supply chain

-

Pharma: Ensuring compliance with serialization laws

Step 2: Select the Right RFID Technology

| RFID Type | Best For | Read Range | Cost |

|---|---|---|---|

| Passive UHF RFID | Bulk material tracking | 1-10m | Low ($0.10-$1/tag) |

| HF RFID (13.56 MHz) | Tool tracking, workstations | <1m | Medium |

| Active RFID (Battery-powered) | High-value asset monitoring | 100m+ | High ($20-$100/tag) |

Hardware Checklist:

✔ RFID Tags (Durability: High-temp, chemical-resistant?)

✔ Fixed Readers (For choke points like dock doors)

✔ Handheld Terminals (For mobile scanning)

✔ Middleware/Software (ERP/MES integration)

Recommended Hardware:

-

Fixed Reader: Impinj R700

-

Handheld Scanner: Zebra MC3330xR

-

Rugged RFID Tags: HID SureTag

Step 3: Pilot Testing (Before Full Rollout)

-

Choose a small area (e.g., one production line).

-

Tag 50-100 items and test scanning accuracy.

-

Validate data flow to your ERP/MES system.

-

Train a super-user team to troubleshoot.

Common Pilot Challenges:

-

Metal/water interference (Adjust tag placement)

-

Reader collision (Optimize antenna positioning)

Step 4: Full-Scale Deployment

-

Phase 1: Tag all critical assets & materials.

-

Phase 2: Install fixed readers at key checkpoints.

-

Phase 3: Integrate with ERP (SAP/Oracle) or MES.

-

Phase 4: Train staff & monitor performance.

Pro Tip:

Use color-coded RFID tags for quick visual identification (e.g., red for scrap, green for approved parts).

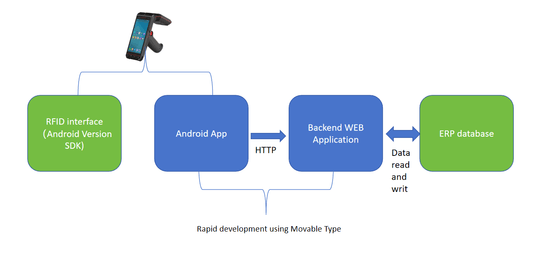

Step 5: Integration with Manufacturing Systems

-

ERP Integration: Sync RFID data with SAP, Oracle, or NetSuite.

-

MES Connectivity: Enable real-time WIP tracking.

-

Dashboard Analytics: Track KPIs like OEE (Overall Equipment Effectiveness).

Software Options:

-

Low-Code Platforms: PTC ThingWorx, Siemens MindSphere

-

RFID Middleware: Impinj ItemSense, Zebra Savanna

Step 6: Staff Training & Change Management

-

Workers: Teach basic scanning & troubleshooting.

-

Supervisors: Train on data analytics & reporting.

-

IT Team: Ensure smooth ERP/MES integration.

Training Tip:

Run mock drills where staff locate tagged items using handheld readers.

3. Real-World RFID Manufacturing Case Studies

Case 1: Automotive Assembly Line

-

Problem: Lost/misplaced engine components causing delays.

-

Solution: UHF RFID tags on all parts + fixed readers at stations.

-

Result: 30% faster assembly, zero lost parts.

Case 2: Aerospace Tool Tracking

-

Problem: $500K/year lost in missing calibration tools.

-

Solution: HF RFID tags on tools + mobile check-in/out stations.

-

Result: 100% tool accountability, reduced downtime.

4. Common RFID Implementation Mistakes (And How to Avoid Them)

❌ Mistake 1: Choosing the wrong frequency (UHF vs. HF).

✅ Fix: Test tags in your actual environment first.

❌ Mistake 2: Poor tag placement (metal interference).

✅ Fix: Use on-metal RFID tags or ceramic antennas.

❌ Mistake 3: Ignoring middleware/software integration.

✅ Fix: Partner with an RFID solutions provider early.

5. Future Trends: Smart Manufacturing with RFID

-

AI + RFID: Predictive maintenance using sensor tags.

-

Digital Twins: Real-time RFID data mirroring production flow.

-

5G & Edge Computing: Faster RFID data processing.

6. Leeshion’s RFID Solutions for Manufacturing

For businesses seeking cost-effective, rugged RFID solutions, the Leeshion LS-R501 UHF RFID Terminal offers:

✔ Industrial-grade durability (IP67)

✔ Long-range scanning (8-10m)

✔ Seamless ERP/MES integration

Perfect for:

-

Work-in-progress tracking

-

Tool & equipment management

-

Warehouse automation

👉 Learn more about the LS-R501 here

Conclusion: Your RFID Implementation Checklist

-

Define goals (What will RFID solve?)

-

Choose hardware (Tags, readers, software)

-

Run a pilot test

-

Deploy in phases

-

Integrate with ERP/MES

-

Train employees

Need help? Book a free consultation with our RFID experts to design a custom solution for your plant.

🔗 Further Reading:

Ready to automate your manufacturing process? Get a quote today!

No comments

0 comments